Snowplough 18

Here we look back to 2008 when Bryan started work on Snowplough No 18.

Snowplough 18 originally posted by Bryan B.

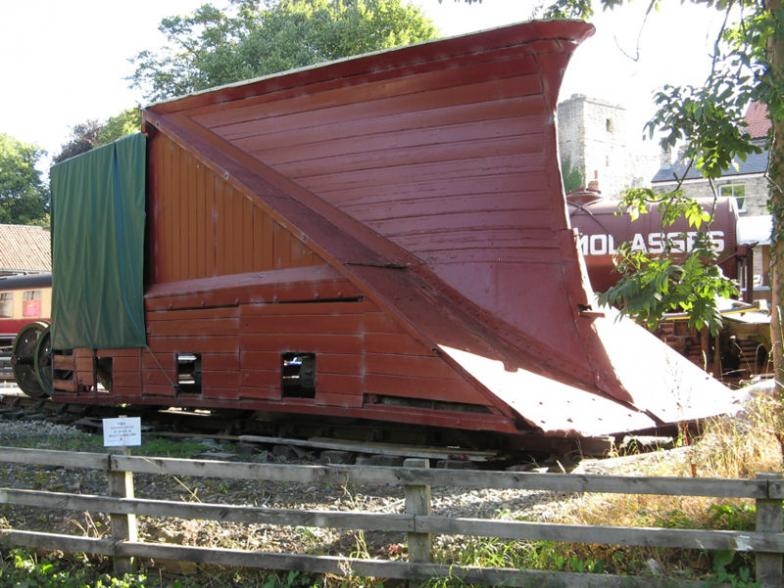

This is the image most people have of Snowplough 18 when it was sat alongside Pickering Station car park for a number of years. As can be seen here the timber work is looking worn out and a definite droop is apparent to the slope.

I decided after having a survey caried out on its condition that major repair work was required on the mainframes and to the structure of the plough slope.

The image below illustrates the condition of the lower timberwork, in some places the mainframes were so bad that you could put your hand through what should have been an oak beam 5 inches thick.

Trip Up North.

I contracted Rail Restorations North East of Shildon to carry out the works and so on the 21st of February 2009 plough 18 was loaded onto Duncan Milners lowloader at Newbridge yard and departed for Shildon via the A64, A1237 York Ring Rd (passing the bottom of my garden) Onto the A59 and the A1 to Shildon in a section of the former wagon works.

From here I left number 18 in the hands of Dave Foxton and his son Steven to carry out the work.

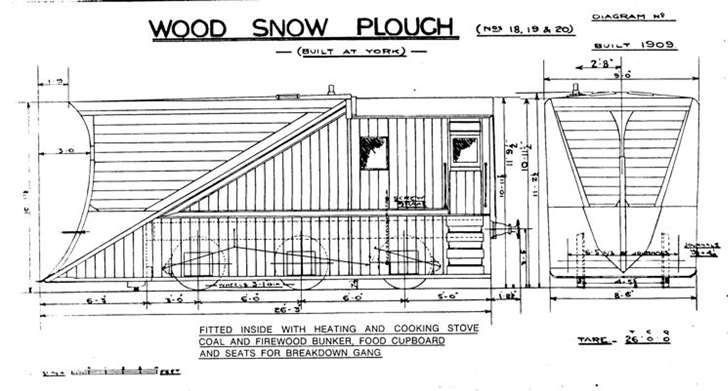

This was to entail the separation of the body from the frame. Removing the ballast decking cast iron slabs before lifting the body off. Each slab is 8ft long by 6 inch by 3 inch thick and are interlocked together, with a single layer in the rear cab section and a double layer to the front, each slab had to be manhandled out of the door.

The body removed using the overhead crane then pushing the chassis out from under and then lowering onto stands.

The chassis rebuilt first. Note the new tie-rods and to the lower right the cast iron slabs waiting re-installation.

Plough Slope.

Once the under frame complete, attention then focused on the repair work required on the plough slope.

The body reunited with the frame to ensure all bolt locations remained true and no distorting the timbers would result.

The slope work would entail the removal of all the slope timbers and replacement in Pitch Pine as per the originals, however all the substructure framing was also in need of replacement. This kept Steven the main worker on the plough very busy making up new sections.

As seen above, timber-work condition not good by any means.

Some parts from the framing reused but not necessarily in the original positions. Where possible, original timber re-used to form a smaller section.

On completion of the slope works the original work contracted for was just about complete. However I felt the opportunity to replace some more awkward posts around the plough which showed rot and decay should not go missed This considering the standard of the timber work carried out up to date. Then fitting new corner posts and splicing in new sections to other posts then carried out.

Fitting of new Oak packing pieces to the buffers was one of the last jobs.

The plough then reloaded onto Duncans lowloader for return to Newbridge yard on the NYMR on the 8th of September 2010.

Compare this photo of the rear buffer beam with the one earlier.

Return back to Newbridge.

Remaining work comprising side skirt panels re-making. A new steel under-tray requires fitted under the slope toe, refit the cutting edge. Secure the steel sheet over the nose, refit the skylights, some attention to the doors and other body timber panels. Repaint into NER Indian Red and whatever else turns up in the process.

Its all a long time since the plough arrived by rail from Gateshead back in 1975. Even then things were not as straightforward as they seem.

As pictured, the plough arrived facing Whitby (not Pickering). So it went back to Thornaby for turning and returned the next day.

During the work carried out prior to going to shildon I recovered numerous fragments of broken wagon plates as additional ballast weight. Unfortunately none complete, these came from wagon scrapping at York in 1909 during Number 18 assembly.

However I did recover some of these other plates.

As part of my research into Number 18s history I have come across a number of photos of it. Regularly paired with Number 20 also built at York in 1909. This also survives at Beamish although not on display. It is in the reserve store and is almost impossible to photograph.

In Film.

Number 18 also featured in the British Transport film “Snowdrift at Bleath Ghyll” in the 1950s and viewable by clicking here to view this film. This was one of the rare times 18 and 20 were apart. One day they may get together again.

The eventual aim is to restore number 18 to a similar appearance to that of the 3rd surviving North Eastern Railway Snowplough Number 12 in the possession of the NRM and on display at its Shildon museum.

Plough 18 featured in an article in Heritage Railway February 2011 issue 147 by Maurice Burns. The full version can be viewed by Clicking Here. As a scan, it may take a while to open up (860K).

Update 9th July 2011.

Thought about time an update on progress.Since the Snowplough returned from RRNE at Shildon, work has concentrated on renewing and repairing the cab bodywork planking on the east / Right hand side. Some of the lower body framing timbers needed replacing as did some of the T+G planking.

However it has been found possible to reuse some of the bearers in different positions. Some planking reused after top and tailing, under the plough slope. New boards purchased for the remainder and then Tongue and grooved to 6 1/4″ standard boards at Newbridge.Lots of drilling, countersinking, screwing and filling then followed. On completion wood primer applied with further filler as required.

New side skirt panels produced from 1 1/4″ T+G. They get heavy I can tell you. I even drafted in assistance from home in the form of my wife Christine.

For the first time during sanding off I found some original lettering. Dating from the 50s.

I know you cannot make it out here but it details Number and Allocation to West Auckland as in this photo below but on the opposite side.

During this time Nick Hutchinson was busy cutting steel sheet, welding and drilling to produce a new toe sheet. This sheet extends back underneath and required a lot of fiddling about to suit the angled bolts from the top sheet.

Re-Paint.

Nick Carter had taken on the task of masterminding the repaint with occaisional assistance from his neighbour Dave. He also managed involving the home authorities recording his tracing work on Plough 12 at the NRM Shildon. Identify the font in use for the lettering.

The first transformation appeared when panels started changing colour to Pink. Well the undercoat was available and originally was the undercoat for West Yorkshire PTE Red. This followed by an intermediate Red Oxide coating.

A new member of the team, Phil Baker who has taken on the task of rebuilding the 2 cab doors.

Phil found a spot near the deck of the plate wagon to carry out the repair work to the doors.

This mainly comprises of stripping the old planking off, cleaning out the inner frame, replacing any rotten frame members. Making sure the droplightswork and waxing the slides, refixing the frame then shaping and fixing new T+G planking.

Top Coat.

Painting has now progressed to the application of the first coat of top coat Indian Red. Currently the rear end and the East side body are painted. Stencils now delivered which Nick will use, enabling the lettering detailing the Snowplough allocation. Enabling the lettering detailing the Snowplough allocation – Bishop Auckland.

More progress expected next week 15th July. On Wed 24th August number 18 became loaded away to Kirkby Stephen for the Stainmore 150th event. Moved by Moveright.

First day in the sun for a while all the better to see the paint in the best light. The lorry had to go into the quarry to turn round once the plough loaded.

On its return from Kirkby Stephen Snowplough 18 has gone on its travels again. This time to the far North.

Grosmont. It has now completed its first return journey on the NYMR taking 36 years to do it.

A first for a GWR loco and an independent Snowplough attached?