Grampus 991840

Here we look back to 2010 when work on Grampus Wagon (991840) commenced.

The on-going saga of returning a Grampus wagon to traffic.

Work started on this Grampus wagon in March 2010 alongside the continuing work on LNER brake van 246710.

From this photo (5th March 2010) it does not look too bad, nothing that a de-rust and paint wouldn’t cure. However take a look over the side.

This picture shows the almost non-existent timber flooring, the bent doors and pillars and misalignment of the body side. The first task was to remove the rubble and what remained of the flooring. The bricks went to the yard for potential recycling and the spoil added to the yard ballast surface.

This photo again on the 5th March 2010. shows another missing item. A removable channel section. This has now been located and fitted.

Original Purpose.

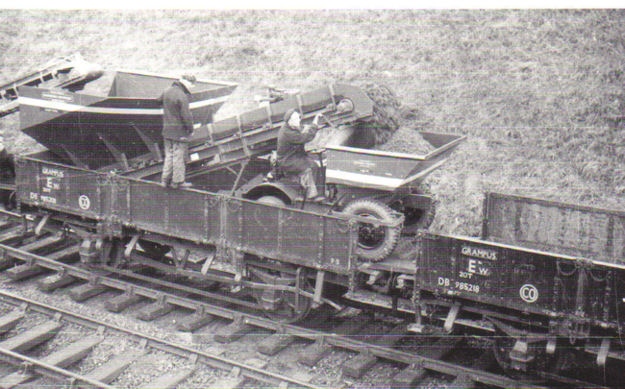

The wagon originally built so a small dumper could travel along the train by drop ends in the body. The lower section is a hinged panel that drops down on the buffers. Above that, are two removable sections with inset timbers that fit within the corner post channel sections.

This shows it in use. Note the drop down panel and plates covering the gap.

The channel sections stowed in angled racks mounted under the body get accessed from underneath the buffer beams. The next stage was to descale the wagon, or at least remove the heaviest corrosion. So out with the chipping hammers and needle guns to get into the awkward corners.

No need to worry about leaving a bit as that would be cured by bringing in the shotblasting contractor. They can remove all the remainder of the rust and spray a coat of grey primer over the wagon. A fair amount of work undertaken at this stage in replacing wasted angle section and strengthening corner gussets.

This photo shows some of the flooring bolts that would need removing, the heavy rusted areas in the corners and as mentioned earlier the channel stowage racks underneath.

The purpose of this wagon joining the fleet is to work alongside the other GRAMPUS 988228 and RUDD 990109. Helping in the disposal of smokebox and fire grate ash originating from the loco stabling facility at Newbridge in the compound alongside the P Way shed.

Ash loaded, usually by crane on a Friday from a skip into the wagons. Then taken to various locations along the railway and used for ballasting in sidings or ground levelling. Pickering Carriage and Wagon sidings, Levisham North end headshunt, the station sidings and Grosmont shed headshunt are just some of the areas visited. 3 wagons are required for the traffic 1 loading, 1 in transit and 1 being offloaded being the idea.

Ash.

If anybody wants any ash then get in contact with Martyn Cannings at Newbridge. No load is too small (if it gets rid of some ash)

The wagon then painted in 1950’s Engineers Black. The outside is not bad for access but the angles under the body mean getting your arms into awkward positions. Guaranteed to get drips up your sleeves or behind your ears. It helped that the chassis was devoid of a floor at this time as it enabled access to be gained both above and from below.

The project is under the management of Nick Carter and usually found wielding a paint brush or using a sander.

Here caught in an action shot complete with graffiti instructions for us. Nick also does all the signwriting by hand.

Flooring.

Because the nature of the load and the frequency that machines offload the vehicle we thought best installing a steel deck floor. Previously done with GRAMPUS 988228 and seems successful so we have repeated the exercise on 991840.

The first stage is to install some scrap bullhead rail cut to length. Thus keeping the floor height at the original level, though with a slight camber to the sides to facilitate draining.

Welding.

These then welded into position by Nick Hutchinson our tame welder.

Once the rails get positioned, then 5 steel sheets get trimmed to size and fitted in place with backing strips around the joints. All then welded and ground off. The sheets left unpainted as the first couple of loads will wear the paint off anyway.

The door stanchions have needed partially straightening by means of heat and a hammer. In order to ensure that the doors worked properly, we have had to split some of the door sheets adjust the pin locations then re weld the split metalwork. In addition, many of the door pins have had new retaining chains fitted.

Nick Carter has now completed all the signwriting, remaining work is to straighten one of the end channel sections. Also some general maintenance to the brake system and replace two of the brake blocks. Hopefully completed by February, wagon badly needed in traffic.

What next? -but there still remains the LNER brake van E246710 to complete first.

We will wait and see.

Bryan Blundell Friday 11th Feb 2011

Grampus 991840 removed from shed on Thursday 7th April and entered PW use.