Ballast Regulator

Type: Ballast Regulator.

Model: Sollinger Hutte SK73.2.

Built: 1984 Uslar, Germany.

Build Number: 1811.

Engine: Deutz F6L413 F V8.

Transmission: Hydrostatic.

Weight: Approx 30 Tonnes.

Brakes: Hydrodynamic and Friction Disc.

Sollinger Hutte Ballast Regulator History.

Originally built and operated in Uslar Hanover on mainland Europe, latterly in the Netherlands before shipping to the UK. The Sollinger Hutte Ballast Regulator was purchased by Grant Plant (Now Volker Rail) and imported into the UK.

Arrival at the NYMR.

Purchased by the NYMR, 2003. Originally built to continental loading gauge, because of continental load gauge, care must be taken at certain locations with clearances. Additionally the access steps modified and some other parts allowing full passage through the North Yorkshire Moors Line.

What does it do?

It has 2 main purposes.

1. Ploughing

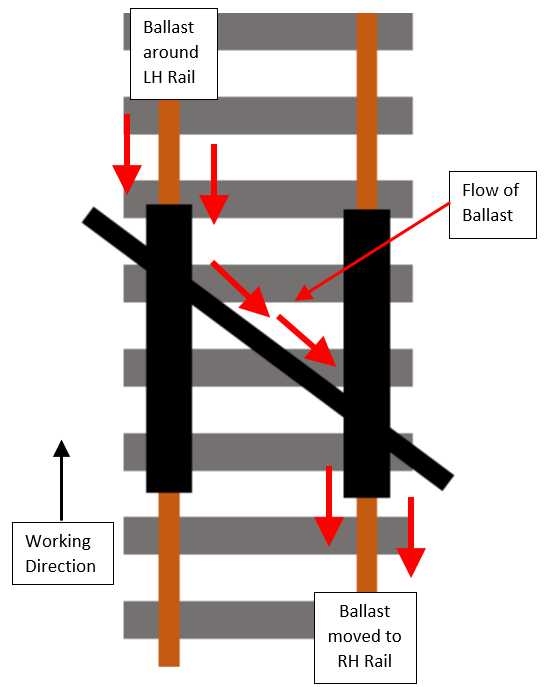

When new ballast has been deployed, it may deploy in heaps and un-even. Under the machine are ploughs that can collect the ballast and move it to the required position. It is even possible to move ballast from the outside edge from one rail and place it towards the outside edge of the other rail.

In the example on the right, the ploughs can be setup to move ballast from the left rails over to the right rails. However various position combinations achieved by different positioning the ploughs.

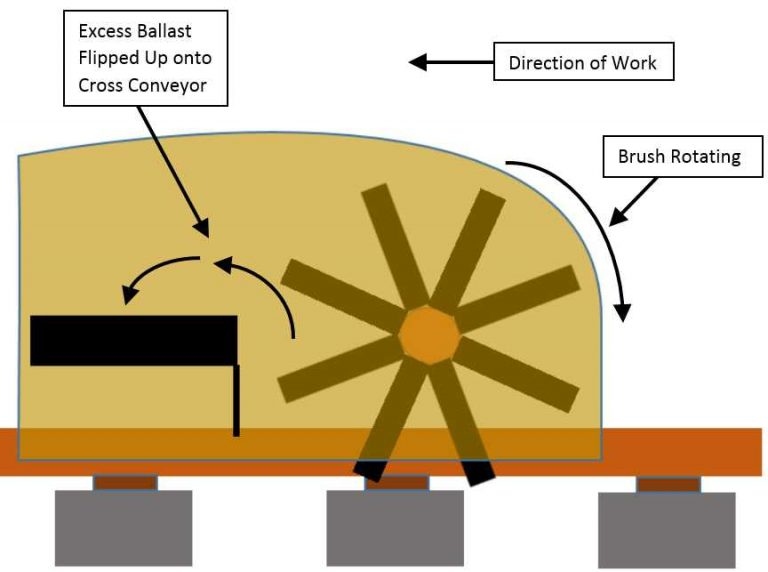

2. Brushing

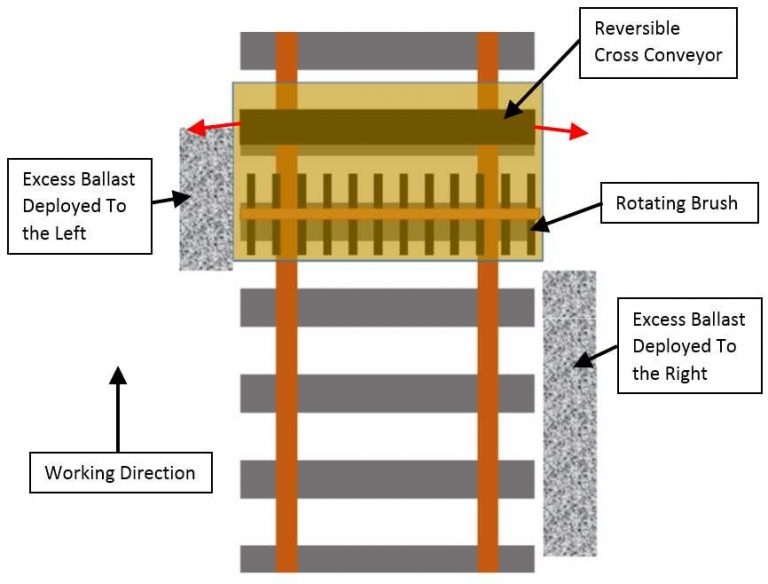

Fitted on the machine rear, the “Brush Box”. This contains a rotating brush which can sweep the ballast and even it out further, or even pick up excess ballast and place it onto a “Cross Conveyor” for deploying around the sleeper ends.

Cross conveyor direction selected to deploy ballast either around the left or right around the track.

As seen below, especially good results achieved with new ballast!

This machine is in active service on the NYMR for regular Track Renewal and Maintenance work!

Chiefly operated and maintained by volunteers from the base at Newbridge.